Galaxy Industrial Equipment is a Fluid Mixing Equipment manufacturing company with integrated engineering solutions.

Thursday, 18 February 2021

Applications Of Side Entry Mixer

Thursday, 11 February 2021

What is Heat Exchangers ,Their Types and Applications

Thursday, 28 January 2021

HOT WATER GENERATION SYSTEMS

HOT WATER GENERATION SYSTEMS

Galaxy process is a silent, immediate hot water generator manufacturer. It is designed exclusively for the hot water needs of hotels, hospitals, resorts, swimming pools, cheese shops, laundries and several other processing industries.

The hot water generator can be placed under pressure or under pressure, depending on the required water temperature.

If the required water temperature is below 100 ° C, the hot water generator does not need to be under pressure, as the boiling point of water at atmospheric pressure is 100 ° C. depends on the required exhaust temperature together with the safety.

Construction for hot water generator project (GALAXY PROCESS)

Our hot water generators are designed with high precautions, such as having the safety valve on top of the housing so that the housing does not exceed the projected pressure.

Depending on the capacity of the hot water generator, the required hot water outlet temperature and the type of fuel to be used to determine the hot water generator design. In general, GALAXY PROCESS is a shell and pipe, chimney shape, but smaller capacities can be produced in a water pipe design.

The multiple passages of flue gases guarantees maximum efficiency, where hot water generators offer low operating costs.

Read also: Chemical treatment for boiler water

Heating options for hot water generators

Gaseous fuels - LPG or CNG

Advantages of hot water generators

• Fully automatic unit

• No-hassle operation

• Outside the scope of IBR.

• High system efficiency

• Ease of installation and Minimum site work

• You can use different fuels according to local availability

ReactorPressure Vessel Manufacturer In India | Mechanical Pan Circulator Manufacturer

In India | Agitator Stirrer Manufacturer In India | High Speed Disperser

Manufacturer In India | Side Entry Mixer Manufacturer In India

Wednesday, 20 January 2021

Reactors Pressure Vessels Of Galaxy process

The offered range comprises industrial chemical reactors, chemical process reactors and others and delivers superior support in handling of chemical processes in different industry sectors. Here, our expertise lies in making these available in different capacities ranging from 100 liters to 50,000 liters and others as specified by the customers.

Reactor PressureVessel Manufacturer In India | Heat Exchanger Manufacturer In India |

Monday, 11 January 2021

Reactor Pressure Vessel Manufacturer In India

Pressure vessels for reactors: metallurgy and manufacturing

I received several comments about the information I provided over time about reactor pressure vessels and I also received requests for additional information. As a result of this contribution, I prepared the following brief discussion about the reactor vessels.

REACTOR PRESSURE VESSELS: METALLURGY AND INSTALLATION

A few short points will begin with this presentation.

The reactor vessels for light water-cooled reactors are made of low-carbon steel alloy to ensure strength

These containers are normally lined with stainless steel to provide corrosion protection against the water used as a reactor refrigerant.

Reactor barrels are difficult, time-consuming and expensive to manufacture due to the absolute need for near perfection in moulding, welding and machining.

Let's start with an investigation into the reactor being manufactured for the first major commercial nuclear power plant in the United States - the Shipping port Atomic Power Station.

Mechanical Pan Circulator Manufacturer In India | Reactor Pressure Vessel Manufacturer In India | Agitator Stirrer Manufacturer In India | High Speed Disperser Manufacturer In India | Side Entry Mixer Manufacturer In India | Heat Exchanger Manufacturer In India | Galaxy Industrial Equipment | Mechanical Pan Circulator | Agitator Stirrer | Side Entry Mixer | Mechanical Circulator | Side entry mixer in India | Side Entry Mixer Manufacturer

Friday, 11 September 2020

What is a heat exchanger?

Suppose you

have a gas central stove (boiler)

that heats a hot water radiator in different rooms of your house. It works by

burning natural gas, forming a line or grid of hot gas jets on top of the water

flowing through a network of pipes. As water is pumped through the pipes, the

heat energy is absorbed and heated. This arrangement we call through the heat

exchanger: the gas jet cools and the water heats up.

A heat exchanger is a

device that allows heat from a fluid (liquid or gas) to flow into a second

fluid (another liquid or gas) without the two fluids having to mix or come into

direct contact. If that's not completely clear, consider this. In theory, we

could get the heat from a burst of gas just by pouring cold water on it, but

then the fire would go out! The important principle of the heat exchanger is that it

transfers heat without transferring heat-carrying fluids.

Thursday, 16 July 2020

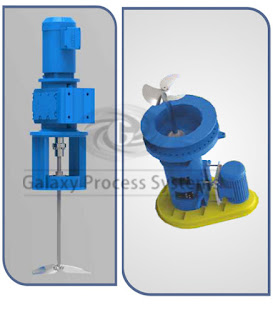

Top Mounted Mechanical Circulator

|

| Mechanical Pan Circulator Manufacturer in India |

Top mounted mechanical agitator stirrer consisting of:

- An agitator carrying vanes or other propelling means

- Shaft connecting the impeller to the driving system. The shaft is supported on

- bearings and is guided by central bush.

- A driving system consisting of electric motor and gearbox.

Advantages

- Savings of strike time up to 30%

- Good circulation throughout the strike

- More uniform grain size

- Increase the capacity of the pan by 25-30%

- Increased crystalline yield up to 7%

- The color shrinkage went from 88% without agitator to 92% with an agitator

- The level of impact in pots can be increased from 25 to 30 cm using an agitator

- Compact and inexpensive design

- Closed housing for bearings for long life

- Easy operation

Friday, 10 July 2020

Mechanical Pan Circulator Manufacturer in India

|

| reactor pressure vessel manufacturer |

- double jacket reactor.

- Limpet Reactor.

- autoclaving.

- GMP models.

- Pressure vessels.

Wednesday, 8 July 2020

Reactor And Pressure Vessels Manufacturer

|

| reactor pressure vessel manufacturer |

- double jacket reactor.

- Limpet Reactor.

- autoclaving.

- GMP models.

- Pressure vessels.

Thursday, 19 March 2020

MECHANICAL PAN CIRCULATOR

Tuesday, 17 March 2020

Agitator (device)

Thursday, 12 March 2020

Pressure vessel

Monday, 24 February 2020

Mechanical Pan Circulator

It is used in vacuum pans to provide better and stronger circulation of the muscuit, which results in better heat transfer and therefore shorter boiling times. Less sugar coloration and increased bread yield.

- High product quality

- Compact design

- Low steam consumption

- Easy to install

- Sturdy structure

- Low cost maintenance

- Easy maintenance

- Shortening of boiling time

- Standardized sugar color

- Uniform crystal size

- Shaft mounting gear

- Durable sealing

Monday, 20 January 2020

Reactor Pressure Vessel Manufacturer In India

- Easy installation

- Minimal maintenance

- chemical resistance

- Excellent quality, competitive price, stable guarantee system.

- Packaging and painting to customer requirements.

- Excellence under pressure.

- Easy and easy transport.

- High strength

- Cosmetic processing

- Chemical industry

- Paper and pulp industry

- Pharmaceutical processing

- Energy processing

- Fuel industry

- Corrosion resistance

- High strength

- lightweight

- Easy and convenient installation

- Automotive

Saturday, 24 August 2019

Side Entry Tank Mixers | Galaxy Industrial Equipment

Wednesday, 10 July 2019

Agitator Stirrer Manufacturer in India | Galaxy Industrial Equipment

- H/D: Variable up to 3:1

- Unit Sizes: 100 to 20000 it are working volume

- Defined surface finish (Dry Grinding) to ra <- 0.8M

Thursday, 20 June 2019

Heat Exchangers Manufacturers In India | Galaxy Industrial Equipment

- Shell

- Tube Bundle

- Stationary header

- Rear header

Modularity for Flexibility Tranter Plate heat exchangers provide excellent efficiency in transferring heat from one

Compact Design Due to its high efficiency, the Tranter Plate heat exchanger saves floor space and floor space far beyond what can be done with shell and tube heat exchangers of the same load. Tranter Plate heat exchangers occupy 20-50% of the shell and tube footprint, including service and maintenance space.

Self Cleaning Action The unit's velocity profile and induced turbulence continuously remove dirt deposits from the heat transfer surface during operation, thereby reducing dirt. Plate turbulence also reducing the need to disassemble the exchanger. increases the effectiveness of the water backwashing and place-in-place (CIP) procedure,

Remarkable features of Galaxy Heat Exchanger:-

- Suitable For 2-Phase Application.

- Can Handle High Level Of articulate Material

- Suitable For High Temp.& Pressure Compatibility

- Flexible In Design

- Mechanically Simple In Design

Galaxy Industrial Equipment Pvt Ltd. provides complete fluid mixing solutions for all process needs!. Our team is 15 years experience in the equipment manufacturing, mixing process design and Heat Exchanger manufacturing in India.

We are emerging as the dominant Heat Exchanger equipment manufacturing company

If Interested! You can contact us at sales@galaxyprocess.in or visit us at www.galaxyprocess.in. You can also call us at 99231 33933.