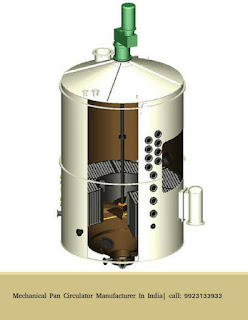

Mechanical

circulators are installed in a vacuum pan to reduce the color of the sugar,

along with an increase in the production of pans to reduce boiling time. Due to

the increase in heat transfer coefficient, the accumulation time is reduced by

up to 30%, thereby increasing the unit's production capacity.

The mechanical construction of the circulator consists of a motor

driving gearbox that reduces the speed required for the connected shafts and

impellers. The sealing is arranged between the circular and the pan to maintain

the vacuum. This seal may be of a packed gland type. Variable speed direct

torque control drive (VFD)

is used to operate the motor.

The drive is programmed to run as fast as possible

while keeping the motor within the allowable power and torque capabilities. If

the masculine viscosity

increases, the drive senses an increase in the required torque and slows the

motor from overloading any component. If for muscular cooling, the drive

travels when the muscovite viscosity increases at the lowest speed of driving.

Technical Superiority:

• It

is commonly used in the sugar industry to enhance the efficiency of the crystallization process.

• A, B

and C can be used for massaiites.

• Improves

heat transfer efficiency by imposing higher rates of heat transfer and evaporation.

• Avoid

loss of head and less deposition on the tubes due to Friction of

circulating crystals.

• Uniform

and Compatible crystal formation.

• colour Less in the sugar and

reduced risk of sugar losses by local overheating with low risk of smelting of crystals.

• Possibility

of feeding the pan with syrup and molasses tank .

• Opportunity

to use low steam pressure for heating.

• Centrifuge

washing water use less .

• The

use of low pressure steam can result in reduced steam consumption.

Key Design Features:

• Process design basis

adopted over the Traditional thumb rule approach of pan tonnage based motor rating selection.

• Saving in time up to

30% for the strike.

• Maximum heat reached by

the massecuite substantially

lower.

• Rugged heavy duty

design.

• Mechanical arrangement

to ease maintenance activity.

• Options of gearbox

types – planetary, inline helical, bevel helical arrangements.

• Genuine material

specifications with material test certificates.