It is used in vacuum pans to provide better and stronger circulation of the muscuit, which results in better heat transfer and therefore shorter boiling times. Less sugar coloration and increased bread yield.

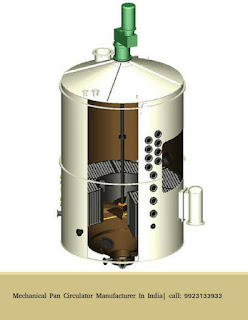

Produce high-quality Mechanical Pan Circulator designed to provide strong circulation and qualitatively and quantitatively improve sugar yield.

A mechanical circulator is attached to the vacuum pan to reduce boiling time, increase bread yield and reduce sugar color. As the heat transfer coefficient increases, the strike time is reduced by up to 30% and the unit's capacity increases.

The mechanical structure of the circulator consists of a motor that drives the gearbox, reducing the speed required for the connected shaft and impeller. A sealed structure is provided between the circulator and the pan to maintain a vacuum. This seal is of the packing gland type. Drive the motor using a variable speed direct torque control drive (VFD).

The drive is programmed to operate at the fastest speed possible, while maintaining the power and torque capabilities of the motor. As the viscosity of the mass cut increases, the drive senses the required increase in torque and slows down the motor to prevent component overload. The drive will trip if the mass viscosity increases to the point where the drive is operating at the lowest acceptable speed due to motor cooling.

Features Mechanical Pan Circulator:

- High product quality

- Compact design

- Low steam consumption

- Easy to install

- Sturdy structure

- Low cost maintenance

- Easy maintenance

- Shortening of boiling time

- Standardized sugar color

- Uniform crystal size

- Shaft mounting gear

- Durable sealing