A heat exchanger may be simply based on a device that is configured to efficiently transfer heat from one medium to another. Heat exchangers are used in a variety of applications, such as heating, cooling, air conditioning, petrochemical plants, refineries and natural gas processing. In many industrial processes allows a heat exchanger to use waste heat from one process to be used in another process, which saves a lot of money, while efficiently.

There are several types of heat exchangers available, depending on their application in various sectors of the industry.

Simply

put, this heat exchanger uses a series of tubes containing the liquid

that must be either heated or cooled, and these tubes run into a

bowl or pipe a lot more one another Liquid contains either heated

and heated tubes or absorbed and cools the liquid in small tubes.

Shell and tube heat exchangers work best in high pressure and demanding environments.

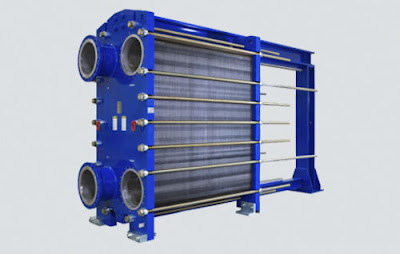

Plate

Heat

Exchanger:

This

heat exchanger works with a network of a plurality of thin and close

plates, which have a very large surface area of the fluid

passages and for a better distribution of heat. Plate heat

exchangers are more convenient compared to hull and pipe

applications in applications where there is a restriction of space.

Adiabatic

Wheel

Heat

Exchanger:

This type of heat exchanger uses a separate material, which can be a

solid or a liquid material to store heat retained, which moves to

the other side of the heat exchanger to be released.

Finned

Plate Heat

Exchangers are

generally made of aluminium alloy with different models such as

cross-flow, counter-current, with different types of fins, which

lead to a transfer Very effective heat. However, they offer a disadvantage at times in the maintenance procedure properly due to

extremely thin plates.

Galaxy Industrial

Equipment Pvt Ltd is a best Fluid Mixing Equipment manufacturing

company in India. Galaxy Industrial Equipment Pvt Ltd is Best Heat Exchanger Manufacturer In India.