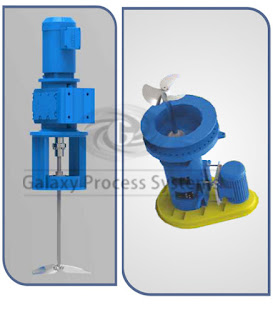

Galaxy Industrial Equipment is a Fluid Mixing Equipment manufacturing company with integrated engineering solutions.

Thursday, 11 February 2021

What is Heat Exchangers ,Their Types and Applications

Friday, 11 September 2020

What is a heat exchanger?

Suppose you

have a gas central stove (boiler)

that heats a hot water radiator in different rooms of your house. It works by

burning natural gas, forming a line or grid of hot gas jets on top of the water

flowing through a network of pipes. As water is pumped through the pipes, the

heat energy is absorbed and heated. This arrangement we call through the heat

exchanger: the gas jet cools and the water heats up.

A heat exchanger is a

device that allows heat from a fluid (liquid or gas) to flow into a second

fluid (another liquid or gas) without the two fluids having to mix or come into

direct contact. If that's not completely clear, consider this. In theory, we

could get the heat from a burst of gas just by pouring cold water on it, but

then the fire would go out! The important principle of the heat exchanger is that it

transfers heat without transferring heat-carrying fluids.

Saturday, 24 August 2019

Side Entry Tank Mixers | Galaxy Industrial Equipment

Thursday, 20 June 2019

Heat Exchangers Manufacturers In India | Galaxy Industrial Equipment

- Shell

- Tube Bundle

- Stationary header

- Rear header

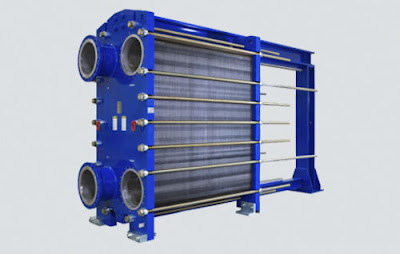

Modularity for Flexibility Tranter Plate heat exchangers provide excellent efficiency in transferring heat from one

Compact Design Due to its high efficiency, the Tranter Plate heat exchanger saves floor space and floor space far beyond what can be done with shell and tube heat exchangers of the same load. Tranter Plate heat exchangers occupy 20-50% of the shell and tube footprint, including service and maintenance space.

Self Cleaning Action The unit's velocity profile and induced turbulence continuously remove dirt deposits from the heat transfer surface during operation, thereby reducing dirt. Plate turbulence also reducing the need to disassemble the exchanger. increases the effectiveness of the water backwashing and place-in-place (CIP) procedure,

Remarkable features of Galaxy Heat Exchanger:-

- Suitable For 2-Phase Application.

- Can Handle High Level Of articulate Material

- Suitable For High Temp.& Pressure Compatibility

- Flexible In Design

- Mechanically Simple In Design

Galaxy Industrial Equipment Pvt Ltd. provides complete fluid mixing solutions for all process needs!. Our team is 15 years experience in the equipment manufacturing, mixing process design and Heat Exchanger manufacturing in India.

We are emerging as the dominant Heat Exchanger equipment manufacturing company

If Interested! You can contact us at sales@galaxyprocess.in or visit us at www.galaxyprocess.in. You can also call us at 99231 33933.

Tuesday, 24 July 2018

Heat Exchanger Manufacturer

|

| heat exchanger manufacturer in India |

- Capacity from 1 Mq to 150 Mq.

- Shell and the type of tube. Floating head type.

- Extended and double sheet type of pipe.

- High efficiency and low energy consumption

- Easy installation

Thursday, 26 October 2017

Exhaust Gas Heat Exchanger

|

| Galaxy process - Heat Exchanger Manufacturer In India |

Wednesday, 2 August 2017

Heat Exchanger : Paper And Pulp Applications

Essentially, the paper process, starting with the processing of wood pulp and processing, then go into bleach and cleaning before paper formation, help with any heat exchanger. More specifically, plate heat exchangers are used to heat liquids that are used to produce wood pulp, a method which comprises chemical compounds which separate the wood structure, wherein a fork-like substance remains , Which can be further formed into paper. Secondary processes include discoloration or death of the pulp, which is a procedure that is heated by a plate or spiral heat exchanger. Once the desired color is reached, the pulp, paper, knitting on a paper machine, which form the paste into thin strips, leaves. Throughout the humidity is eliminated and some type of fan is used to dry completely.

|

| Heat Exchanger |

A part of the paper machine also uses a type of heat exchanger which is known as a waste heat recovery system, which is one of the means that heat exchangers are able to save energy Businesses, resources and money. Heat Recovery Machine is able to absorb heat and moisture in a room to be reused without having to put a larger load on the power source, which normally provides air and water For the paper making process. For the most part, it is a recycling system.Galaxy is Leading Heat Exchanger and High Speed Disperser Manufacturer In India.

Tuesday, 4 July 2017

Types of Heat Exchangers

|

| Heat Exchanger Manufacturer In India |

- Shell & Tube heat exchanger

- plate Heat exchanger

- Regenerative Heat Exchanger

- Adiabatic wheel heat exchangers

Shell & Tube Heat Exchanger:

Tube heat exchanger are made up of several tubes, circulates through the liquid. The tubes are divided into two sets: the first set contains either heated or liquid cooled. The second assembly contains the liquid which is responsible for the initiation of the heat exchange and exhaust heat either from the first set of tubes by absorption of cooling heat and substantially transmits the heating fluid or the phrase by Its own heat pressed against the liquid. In interpreting this type of heat exchanger Caution must be exercised in determining the correct wall thickness and pipe diameter to allow an optimal heat exchange. With regard to the flow envelope and the heat exchanger tube can take one of the three flow path patterns. Galaxy is best Heat Exchanger Manufacturer In India.

Plate Heat Exchanger:

Plate heat exchangers consist of thin plates, which are connected to one another, with a small amount of space between each plate, which is generally held by a small rubber seal. The surface is large and the corners of each rectangular plate have an opening, can flow between the plates through the fluid, wherein heat is extracted from the plates as it flows. Change themselves fluid channels hot and cold liquids, which means that the heat exchanger can actually cool and heat liquid - they are often used in refrigeration applications. Since plate heat exchangers have such a large area, they are often more efficient than the shell-and-tube heat exchanger.

Regenerative Heat Exchanger:

In a heat exchanger with regeneration of the same fluid is directed on both sides of the heat exchanger, which may be either a plate heat exchanger or a tubular heat exchanger. Since the liquid can become very hot, the outgoing liquid is used to heat the incoming fluid, in which a substantially constant temperature is maintained. In a regenerative heat exchanger a large amount of energy is recorded because the process is cyclical, with virtually all of the relative heat of the outgoing fluid to the inflowing fluid being transmitted. To maintain a constant temperature, only low energy must be required to increase the temperature of the total and lower liquid.

Adiabatic Wheel Heat Exchangers:

In Adiabatic Wheel Heat Exchangers, a middle of the road liquid for warm capacity is utilized, which is then exchanged to the inverse side of the exchanger unit. An adiabatic wheel comprises of a huge wheel with wires that go through fluids - swinging to remove warmth or exchange - both hot and frosty.

Galaxy is Leading Heat Exchanger Manufacturer In India and Reactor Pressure Vessel Manufacturer In India.

Thursday, 13 April 2017

Furnace Heat Exchanger

|

|

Heat

Exchanger Manufacturer In India

|

The furnace heat exchanger used fuel - propane, natural gas or oil - to generate heat. The air motor of the blower or fan then projected onto the heat exchanger and into the house of the house, which distributes it throughout the house. Pretty simple, right?

To explain a little more, ignite the burner's combustion gases. The gases are sent to the heat exchanger where heat is transferred from the gases to the walls of the heat exchanger.

As the gases cool, the train fan directs in induction evacuation tubes and they are exhausted from the house. This is done at the same time when the hot air absorbs combustion gases before its distribution through the heat of the pipeline from the walls of the heat exchanger.

Tuesday, 14 February 2017

Plate Heat Exchanger Manufacturer In India

|

|

Heat

Exchanger Manufacturer In India

|

Gasketed Plate Heat Exchanger :

Elastomeric Gasket are provided between two disc channels to provide flow pattern according to design conditions.

Semi-Welded Plate Heat Exchangers :

Alternatively, a pair of plates are welded together to form a Semi-Welded plate heat exchanger. Between the two pairs of welded plates are provided elastomeric seals

CHARACTERISTICS

- Connections : screw / drawn / flange / screwed

- Design Standards : ASME / PED / DIN

- Consulting equipment : SS304 / SS316L / Ti / SMO 254 / Hastelloy

- Sealing material : NBR / EPDM / HEPDM / CR / Viton / PTFE

- Pressure / temperature : · 6 to 30 bar / -20 to 240 ° C

- Flow rate / PHE : 4-1200 m3 / h

Monday, 23 January 2017

Introduction of Heat Exchanger

|

| Heat Exchanger Manufacturer in India |

Various mediums of heat exchange

- Water for water

- Water for oil.

- Water with gas.

- Steamed water.

- Water to air.

- Water with refrigerant.

- Oil with refrigerant

- Evaporator

- Condenser

- After cooler

- Inter Coolers

- Oil cooler

- Specific heat exchanger

- Customized Heat exchangers.

Air conditioning and Refrigeration equipment.

- .Single circuit evaporator, multi-circuit.

- .Single circuit capacitors, multiple circuits.

- . water-to-water heat exchanger.