Galaxy Industrial Equipments Pvt. Ltd. is a leading manufacturer, supplier, exporter of

high-quality heat exchangers. For efficient operation, most industrial applications use some

type of cooling medium, which is generally fluid. Heat exchangers are used to cooling such

fluids. Heat exchangers are industrial devices that transfer heat from one medium to

another during the manufacturing process.

Heat is transferred by conduction and convection through the exchanger material which

separates the media being used. The hot fluid is cooled by dissipating heat into the cold

medium. Heat exchangers are widely used in various industrial applications such as

injection molding machines, blow molding machines, hydraulic presses, furnaces,

pharmaceutical plants, food processing, dairy products, chemical processes, engines, and

refrigeration. There are two types of heat exchangers: shell & tube type heat exchangers and

gasket plate type heat exchangers. Galaxy Industrial Equipments Pvt. Ltd. offers both types

of heat exchangers.

Shell and Tube Heat Exchanger:-

The shell-and-tube type heat exchanger regulates temperature fluctuations in the tube, and

liquids such as oil and water flow through the shell pipe by dispensing coolant. The fluid to

be cooled passes zigzag through the shell around a tightly mounted copper tube with a large

number of baffles. The liquid transfers heat to the water and the water flowing through the

copper tube follows multiple paths. This improves the water-fluid contact time for optimal

heat transfer. This makes the heat exchanger very efficient.

Following a section of the shell and tube HE:-

- Shell

- Tube Bundle

- Stationary header

- Rear header

Plate Heat Exchanger:-

Tranter has just begun supporting 50 years of engineering, manufacturing and gasket plate

heat exchangers. We listened carefully to our customers. Not only do we buy plate heat

exchanger that meet the specifications, but we also tell us that they want value-added

solutions with easy-to-maintain design and life-cycle support.

Modularity for Flexibility

Tranter Plate heat exchangers provide excellent efficiency in transferring heat from one

liquid to another or from steam to liquid. This modular switch combines frames, plates, and connections to form various configurations.

High Heat Transfer Rate

Tranter is a market leading in the development of high-efficiency plate pattern design. Ultraflex plate patterns, our unique neutral face gasket groove design, and the ability to configure our units in either parallel or diagonal flow configurations. These options improve utilization of available pressure drop and increase the efficiency of our units. Our diagonal flow options are especially important at larger currents and lower NTU duties.

Compact Design

Due to its high efficiency, the Tranter Plate heat exchanger saves floor space and floor space far beyond what can be done with shell and tube heat exchangers of the same load. Tranter Plate heat exchangers occupy 20-50% of the shell and tube footprint, including service and maintenance space.

Self Cleaning Action

The unit's velocity profile and induced turbulence continuously remove dirt deposits from the heat transfer surface during operation, thereby reducing dirt. Plate turbulence also reducing the need to disassemble the exchanger. increases the effectiveness of the water backwashing and place-in-place (CIP) procedure,

Remarkable features of Galaxy Heat Exchanger:-

- Suitable For 2-Phase Application.

- Can Handle High Level Of articulate Material

- Suitable For High Temp.& Pressure Compatibility

- Flexible In Design

- Mechanically Simple In Design

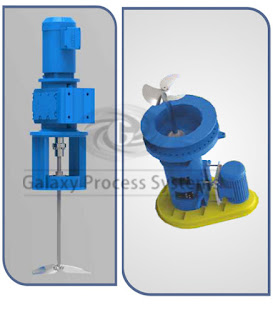

Galaxy Industrial Equipment Pvt Ltd. provides complete fluid mixing solutions for all

process needs!. Our team is 15 years experience in the equipment manufacturing, mixing

process design and Heat Exchanger manufacturing in India.

We are emerging as the dominant Heat Exchanger equipment manufacturing company

conveying better values to employees, customers, and stakeholders.

Our first priority is to enhance customer satisfaction and experience with service. Generate

trust through service.

If Interested! You can contact us at sales@galaxyprocess.in or visit us at

www.galaxyprocess.in. You can also call us at 99231 33933.