Side

entry mixer is an efficient converter of mechanical energy in a fluid motion.

Side entry mixers are more efficient than top entry mixers. For large-diameter

tanks, it is significantly cheaper Side entry mixer is ideal for use in

floating roof tanks. When practical considerations prevent the use of top entry

mixers.

Application

of Side Entry Mixers

Crude

Oil Bottom Sludge & Water Pocket Control: - To

control or prevent bottom accumulation Sludge and water pocket (BS & W)

Polishing requires high-speed circulation Keep the bottom of the tank

completely Heavy solids, water, corrosive salts in suspension.

Maintain

Homogeneity: - Finished or to maintain refinery homogeneity

Intermediate products or chemistry. This requires a complete movement of the

entire tank. "Turnover" from top to bottom and circulation around the

tank, Make sure the product is at the top, center, and bottom Remain uniform

Specification. This may also apply to crude oil direct storage in refinery

tanks in particular Distillation unit.

Blend:

- To get a mixture of two or more different components a specific

homogeneous blend at a specific time Requirements.

Heat

Transfer: - To support heat transfer during heating or cooling,

or Maintains temperature uniformity and complete fluid Motion.

Combined

Duties: - One or more jobs may apply Specific applications

and most important obligations. You need to decide on the choice of mixer.

Typically, the duty that requires the most power is a blend.

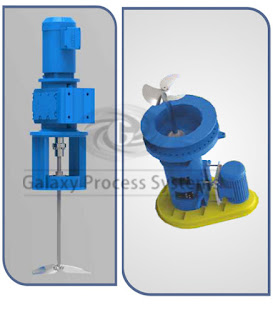

Types

of Side Entry Mixer

Fixed

Angle: - Used and maintained in blending applications helps

with uniformity and heat transfer. All these The application requests full

top-to-bottom sales For this purpose, the mixer is permanently installed At an angle

of 10 ° to the left of the tank axis.

Swivel

Angle: - The swivel angle mixer inlet angle varies up to 30 °

on either side. The centerline of the tank is activated in 10 ° increments tank

floor washed directly by impeller flow. This is the only satisfactory solution

for BS & W control. Large tanks and heavy solids, with water corrosive

salt. A permanently fixed mixer is maintained by the suspension of the mixer

module is supported by two hinge bearings Makes it easy to change the angle

manually. A side-entry mixer with swivel capability can change the shaft angle

by 15 degrees on either side of the mixer, allowing the tank floor to be scored

directly by the high flow generated by the impeller. Turn with motor & hard

& solid swivel ball. The mixer angle can be changed manually or with an

automatic swivel actuator. Side entry mixer with geared motor single or double

(cartridge type) mechanical seal depending on application and process

requirements. The shut-off device gives you the flexibility to change the

mechanical seal without emptying the tank. A large tank with multiple side entry

mixers for liquid mixing and solid suspension.

Interested? You can call us +91-9923133933 and contact us on galaxyprosys@gmail.com and also visit us for more details www.galaxyprocess.in

No comments:

Post a Comment