Tube heat exchanger

characteristics

Applications

Advantages:

Galaxy- process is the mechanical pan circulator manufacturer in India. Looking for heat exchanger manufacturer in India, GALAXYINDUSTRIAL EQUIPMENT PVT. LTD. is the best option.

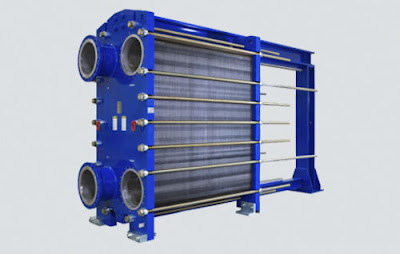

The

tube bundle heat exchanger is the most common heat exchanger in oil

refineries and other large chemical processes and is suitable for higher

pressure applications. Tube tubes Heat exchangers are classified as solid and floating heat exchangers. Heat exchangers with a fixed type are used when there is no possibility of mixing two liquids together.Tubular bundle heat exchangers consist of a series of tubes. One set of these tubes contains the liquid, which must either be heated or cooled. The second liquid passes over the tubes which are heated or cooled so

that they can provide the heat or absorb the required heat.In this way, the bottom of the tube is fully welded to the shell and functions as a shirt flange. Floating

heat exchangers have the advantages of dismantling the tube bundle and

access for cleaning the inner and outer sides of the tubes and shell.

|

| Galaxy process - Heat Exchanger Manufacturer |

characteristics

- Shell-tube heat exchangers dispense process fluid and other cooling water or air.

- It is an effective way to save energy.

- Two-phase heat exchangers can be used to heat a liquid to boil it in a gas.

Applications

- heating

- cooling

- air conditioner

- power stations

- chemical plants

- petrochemical plants

- oil refineries

- natural gas treatment

- Wastewater

Advantages:

- The shell tube heat exchanger is often easy to maintain, especially with the models.

Galaxy- process is the mechanical pan circulator manufacturer in India. Looking for heat exchanger manufacturer in India, GALAXYINDUSTRIAL EQUIPMENT PVT. LTD. is the best option.